TSX technology

The TSX technology ensures a total remobilisation of the binder, which is essential to guarantee the hard-wearing of road surfaces produced at very high recycling rates.

Respectful of the environment, it guarantees even lower emissions than those allowed by current restrictions.

Recycling from 0 to 70%

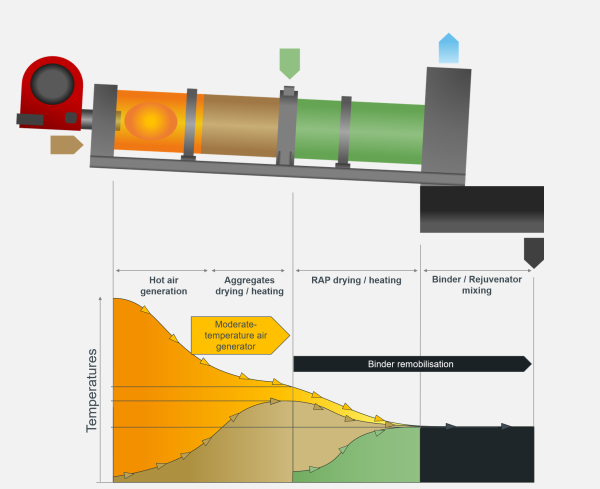

Invented in 2020 by ERMONT, the TSX technology is the result of ERMONT’s 40 years of experience in recycling technologies. Based on a drying process using one single drum, linked to a continuous mixer with 2 synchronised shafts, the TSX technology is the only technology that makes it possible to recycle up to 70% of RAP with a single burner, while preserving RAP and ensuring total remobilisation of the binder.

The dryer drum has three zones:

- Combustion chamber

- Aggregates drying & over-heating + lowering of gases' temperatures + anti-radiation screen

- RAP drying & heating + binder transfer from RAP to aggregates + binder remobilization (initial phase)

The twin shaft mixer, placed after the drum, ensures the blending of imported bitumen to finalise full-binder remobilisation.

Advantages

- New technology born from 40 years of experience

- Very high recycling rate (up to 70%)

- RAP protection

- Respects the environment

- Flexibility

- Full binder remobilisation

- Flawless HMA quality