TSM technology

With 40 years of experience, it remains the best technology with parallel flow, from a technical and environmental viewpoint, delivering a very high thermal efficiency.

It has mainly contributed to the French highway network development. It is also often mentionned as a worldwide reference and mainly used for roads construction in emerging countries.

Recycling up to 35%

The TSM Ermont technology (1976) is based on a drying process with parallel flow (materials going forward into the drum in the same way as the drying gas). Designed by Ermont in 1976, this technology has constantly evolved in order to meet with the latest and the strictest environmental rules.

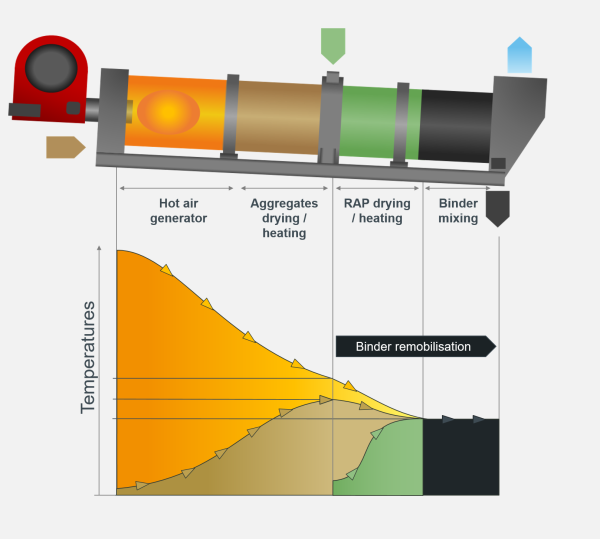

The dryer drum mixer has 4 seperate zones:

- Combustion chamber

- Aggregates drying & heating + lowering of gases' temperatures + anti-radiation screen

- RAP drying + binder transfer from RAP to aggregates + total binder remobilization (initial phase)

- Imported binder mixing + total binder remobilization (final phase)

Advantages

- 40 years of experience

- Simple and tried-out process

- Low operating costs

- High yield

- HMA quality and homogeneity

- Outputs from 40 to 630 t/h

- All mobility types

- Small to very large jobs