RETROFLUX technology

This process designed by Ermont in 1989, was at first the most famous reference globally considering ecology and environment. Since then this technology has been popular worlwide because of its environmentally friendly & economical advantage.

Ermont RETROFLUX technology remains the most environmentally friendly solution, even after 25 years.

Recycling up to 50%

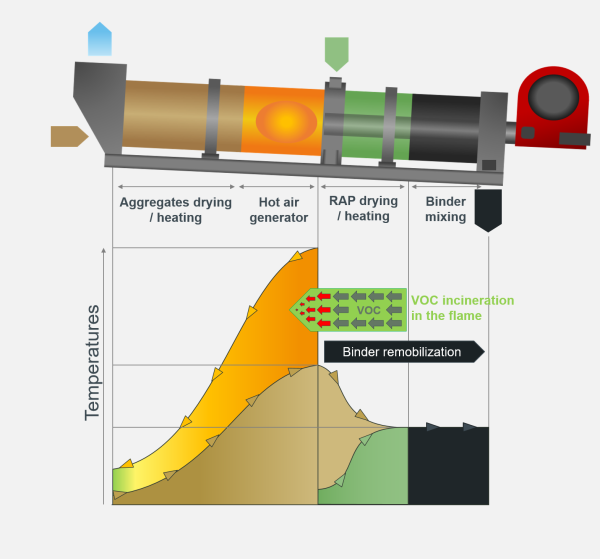

Ermont RETROFLUX technology is based on a counterflow drying process with high performance. The dryer drum mixer has 4 seperate zones:

- Aggregates drying & over-heating

- Combustion chamber

- RAP drying and heating + binder transfer from RAP to aggregates + binder remobilization (initial phase)

- Imported binder mixing + binder remobilization (final phase)

Possible bitumen vapours generated during mixing are totally burnt by the flame of the burner.

Advantages

- 25 years of experience

- High recycling rate (up to 50%)

- Low operating costs

- Energy savings

- HMA quality and homogeneity

- Ecological solution

- Outputs from 50 to 450 t/h

- Small to large jobs

- All mobility types